Table of Contents

ToggleIntroduction

A homogenizer is a powerful piece of laboratory or industrial machinery that breaks down solid and liquid particles into homogenous, uniform mixtures. It is also known as a cell lysor, dispenser, high shear mixer, rotor stator homogenizer, or sonicator. Auguste Gaulin created it in the early 1900s to make milk more consistent.

The main function of a homogenizer is to mix and break down particles or globules into sizes ranging from 0.2 to 2 microns in order to produce a stable emulsion and dispersion. In the same way, homogenizers are helpful for activities like shredding, wetting, dissolving, emulsifying, extracting, precipitating, and breaking cells.

Principle of Homogenizer

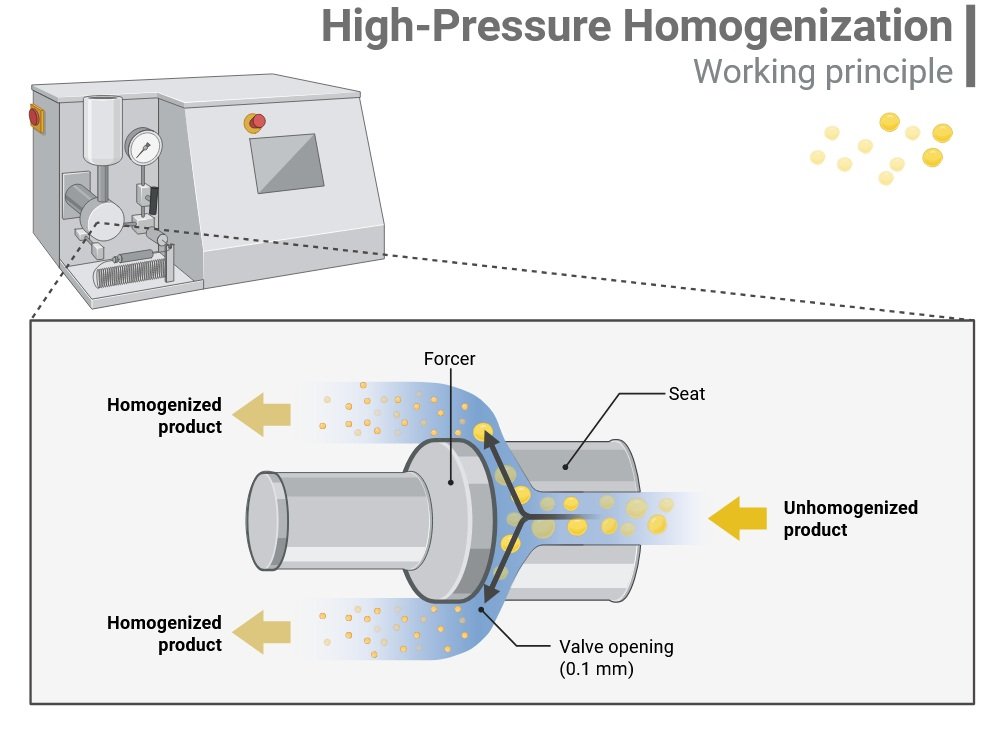

By forcing big globules or coarse particles through a small aperture under high pressure, the homogenizer operates on the basis of converting them into fine globules or particles. As a result, the product has a high level of uniformity and stability.

The combined effects of three main physical phenomena—shearing, turbulence, and cavitation—cause homogenizing activity in a homogenizer.

- Shearing: When a big particle is trapped between the fluid layers of varying speeds, the shearing impact is produced. As a result, the enormous particles are broken down into smaller ones by the shear force, an induced force.

- Turbulence: It happens when fluids move at great speeds. The high speed produces erratic movement in the fluid. The conversion of kinetic energy into internal energy in the form of eddy currents and some heat causes this irregular motion. The eddy current produced aids in reducing bigger particles into smaller sizes.

- Cavitation: When the fluid experiences a large pressure drop, cavitation results. A homogenizer utilizes a pump that is located in front of the homogenizing valve to aid in applying high pressure to the liquid. When the fluid enters the valve, its force is transformed into kinetic energy.

Parts of Homogenizer

- Homogenizing valve: It plays a crucial role in the homogenization process. Its size and shape may vary. Depending on the quantity of valves utilized.

- Homogenizers are divided into two categories: Two-stage homogenizers, which employ two valves, and Single-stage homogenizers, which use just one.

- Valve seat: The opening of the homogenizer is made up of the seat and the homogenizing valve.

- Breaker ring: The valve is made up of a breaker ring. The fluid traveling through the space created by the valve and seat hits the inner wall of the breaker ring at a right angle. Consequently, the bigger particles or globules are transformed into smaller shapes.

- Tension spring: It allows the valve to be held at varying tensions. The fluid pressure causes the valve to rise several thousand inches, which creates the orifice.

- Homogenizing pumps: It applies the necessary pressure for homogenization.

Types of Homogenizers

High pressure Homogenizers: High-pressure homogenizers function by pushing a sample through a small valve or aperture at high pressure. The reduction in particle size is a result of the extreme turbulence and shear forces created by this process. These homogenizers are commonly used in the dairy, food processing, and pharmaceutical industries because they produce fine particle sizes effectively.

Ultrasonic homogenizers: High-frequency sound waves (ultrasound) are used in ultrasonic homogenizers to break up particles in a liquid. Cavitation, which results in the production and destruction of microbubbles, is caused by the ultrasonic waves, which in turn disintegrates particles. Ultrasonic homogenizers are especially helpful in sectors like biotechnology and pharmaceuticals, where heat-sensitive materials are often used.

Bead Mill Homogenizers: By employing beads—usually composed of glass, ceramic, or metal—bead mill homogenizers agitate and break down particles. As the beads interact with one another and the sample, their particle size decreases while they are held in suspension. Bead mill homogenizers are frequently used in the pharmaceutical and biological industries for cell disruption and sample preparation.

Pestle and Mortar: Although conventional mortar and pestle homogenization is still employed, particularly in laboratories for processing small samples. It necessitates physically grinding and crushing samples to achieve consistency.

Handheld Homogenizers: Tissue grinders and homogenizer wands are examples of the compact, portable devices known as handheld homogenizers that are commonly used in labs. A reusable or disposable homogenizing probe and a motorized unit make up their composition. These homogenizers, which are ideal for processing samples on a small scale, are frequently used in biochemical and biological research.

Working of Homogenizer

- The sample is first forced into the homogenization chamber, where it experiences extreme pressure.

- After that, it is pushed through a small opening known as the homogenizing valve. When the material moves through this gap, it undergoes intense shear stress, turbulence, and cavitation.

- These combined forces break down big particles, fat globules, or microbial cells into much smaller and uniform sizes.

- The outcome is a consistent, stable combination with uniformly dispersed particles.

Role of the Homogenizer in microbiology

- Sample Preparation: Microbiological samples might be heterogeneous, including a variety of microorganisms, cells, and debris. Breaking down these samples during homogenization ensures that their chemical makeup is consistent. This is essential for achieving reliable and reproducible results in downstream analyses such as culturing, microscopy, and molecular biology methodologies like PCR and sequencing.

- Cell Disruption: The extraction of cellular constituents like proteins, nucleic acids, and metabolites is necessary for many microbiological investigations. In homogenization, these intracellular components are released into the surrounding solution when cell walls or membranes are broken. With this, researchers are able to separate and examine the contents of cells.

- Detecting Pathogens: Homogenization is a common method for handling clinical specimens that include pathogens in clinical microbiology. By homogenizing the sample, microorganisms are evenly distributed, which improves the chances of finding them via culture-based or molecular methods.

- Environmental Microbiology: Environmental samples, such as soil, water, and sediment, frequently have diverse microbial populations. Homogenization guarantees that these samples are well combined, enabling researchers to collect representative samples for analysis. This is crucial for investigating microbial diversity, density, and activity across diverse environments.

- Food Microbiology: In food microbiology, homogenization is employed to test food items for the presence of microorganisms, pathogens, or pollutants. The microorganisms in the food matrix are evenly dispersed by homogenizing the sample, making them easier to identify and count.

Functions or Uses of Homogenizer

Homogenizers are used extensively in chemical processing, laboratory testing, the manufacture of agricultural products, the food and beverage industry, and pharmaceuticals.

In addition to its application in creating emulsions and suspensions, homogenizer carries out a variety of other tasks, such as:

- It helps to inactivate microbes by breaking the cellular structure of dispersed microorganisms. As a result, it contributes to extending the shelf life of food products.

- It facilitates cell fractionation, which involves cell rupture while maintaining the integrity of the cell’s contents. As a result, the whole inside components that are produced are utilized to create bioproducts for use in agriculture and medicine.

- Enzyme structure may be altered by high-pressure homogenization.

- Enzymes can be targeted for activation or deactivation by adjusting pressure, which is useful in the manufacture of alcoholic beverages.

- It also aids in the isolation of valuable chemicals like lycopene, polyphenols, flavonoids, etc.

Advantages of Homogenizers

- No need for constant mixing.

- Reduces microbial load in food.

- Produces nano and micro emulsions.

- Ensures stability, reproducibility, and consistency.

Limitations of Homogenizers

- More space for microbial contamination.

- Homogenization has a poor energy efficiency in some emulsion/dispersion formulations, with around half of the energy being dissipated as heat.

- The homogenization technique reduces the particle size of liquids, making it unsuitable for the effective production of solid foods or foods containing big particles.

Precautions While Using Homogenizers

- The pressure should be raised bit by bit.

- Never operate the homogenizer when it is dry.

- The device needs to be fed enough to avoid starvation.

- When turning on the homogenizer, the handles on the homogenizing valves should always be let go.

Conclusion

The homogenizer is a powerful tool in microbiology, food technology, pharmaceuticals, and biotechnology. By reducing particle size, creating stable emulsions, and enabling cell disruption, it plays a vital role in sample preparation, pathogen detection, and industrial product development. Despite some limitations, its wide range of applications makes it an indispensable instrument in laboratories and industries alike.

FAQs on Homogenizers

Q1. What is the main function of a homogenizer?

The main function is to break down particles into smaller, uniform sizes to form stable emulsions and dispersions.

Q2. What are the types of homogenizers?

The major types are high-pressure, ultrasonic, bead mill, pestle and mortar, and handheld homogenizers.

Q3. Why are homogenizers important in microbiology?

They help in cell disruption, sample preparation, and pathogen detection for accurate microbiological studies.

Q4. What industries use homogenizers?

Homogenizers are widely used in food, dairy, pharmaceuticals, biotechnology, agriculture, and chemical industries.

Q5. What precautions should be taken while using a homogenizer?

Avoid running it dry, increase pressure gradually, and maintain proper feed to prevent equipment damage.

Also Read

- Nitrogen Fixation and Its Importance in the Ecosystem

- Branches of Microbiology: An Overview of Key Fields

- Importance of Microbiology: Applications, Scope, and Benefits

- What is Microbiology? History, Scopes & Applications

- Microbiology Experiments for Students: A Complete Guide

- Microscopy: Principles, Types, and Applications

- General Microbiology Notes

- Environmental Microbiology Notes

- Molecular & Genetics notes